quality inspector

2018年10月16日星期二

2018 CeMAT digital age intelligent logistics

Digitalization or tradition? This is the key problem facing today's factories, logistics centers and power stations. Industry 4 is rapidly becoming the new standard, which means change. The fourth industry is rapidly becoming the new standard, which means change.

The intellectualization of manufacturing industry has become a topic of common concern all over the world. "Made in China 2025" has always been the focus of attention of the State Council, "Tenth Five-Year Plan" also highlights the development of manufacturing and logistics industry. With the rapid growth of China's economy, especially in the B2C e-commerce field, logistics is becoming more and more important. Developing enterprises will include digital intelligent manufacturing and logistics technology on the agenda of the enterprise.

CEMAT -- the world's leading trade fair for intra firm trade and supply chain management

CETAT will introduce solutions from leading manufacturers of automation, energy and logistics technologies, renowned robotics manufacturers, and global IT and software vendors.

Rapid progress towards more intelligent and integrated production processes is entering the logistics sector in the form of intelligent, connectivity technologies such as robots, UAVs and voice assistants.

The German CeMAT ASIA Trade show is recognized as the most important global conference venue for the entire material handling/internal logistics and logistics Trade Show technology sector.

Every autumn, CeMAT (Asia Logistics Exhibition) is held in Shanghai, with 650 exhibitors exhibiting more than 65000 square meters. These technologies and their impact on logistics will be explored in depth. CEMAT is by far the largest and most important logistics trade exhibition in Asia.

If this year's world's leading industrial technology exhibition is following a central trend, it's the rise of factory artificial intelligence -- and its benefits for workers and production. Add AI to factory machines and robots, and you'll get smart, versatile tools that make life easier for people.

Welcome to the CeMAT-Asia Logistics Trade Show almost everything in this field, such as architecture, systems, accessories, robotic logistics, automotive ID systems, packaging technology, software and so on.

Cemat Asia(Asia Logistics Exhibition) is a 4 day event being held from 6th to 9th November 2018 at the Shanghai New International Expo Centre (SNIEC) in Shanghai, China. This event showcases product from Plant, Machinery & Equipment industry. This event showcases products like Mechanical Handling, Accessories and components for materials handling technology, Entire systems for materials handling technology, warehouse technology, logistics, Warehousing technology and workshop equipment, Material flow control and software etc. in the Plant, Machinery & Equipment industry.

CeMAT ASIA will be held in Shanghai from 6 to 9 November 2018,the CeMat will start parallel with the Hannover fair.

Asia Logistics Exhibition http://www.cemat-asia.com/index.php?lang=en

2018年9月26日星期三

2018 CEMAT Shanghai Asia Logistics Exhibition China

CeMAT in Hannover is the world's leading trade fair for the intralogistics industry logistics exhibition, logistics trade show which takes place since 2014 every two years in Hanover and covers the areas of hoists, cranes, forklifts, warehouse equipment, logistics systems and software. It has established itself internationally as the most important industry gathering and has created successful logistics exhibition in China, India, Russia and South America. No other sector has such great savings and rationalization potentials and is constantly striving to offer more effective solutions. Asia Logistics Trade Show An integral part of the exhibition is a complete network of different processes, jobs, charge carriers, packing units and products. In this context, the Internet and intelligent software is becoming more and more important, because it is needed in order to achieve an efficient linkage and networking of all systems.

The key is safe and reliable technique which is main exhibition focus particularly at CeMAT, ranging from complete systems and intralogistical products on processors and operating elements to software and control systems. The exhibition is divided into five sections: Pick & Pack, Move & Lift, Store & Load, Logistics IT, Manage & Service and pays special attention to the latest innovations and technologies of the industry. Internationally, it is considered as the information and communication platform with global expertise.

On the whole the organisers welcomed on the 5 days of the fair, from 19. May to 23. May 2014, about 1025 exhibitors and 53000 visitors from 65 countries on the CeMAT in Hanover.The CeMAT will take place on 5 days from Monday, 20. April to Friday, 24. April 2020 in Hanover.

Cemat ASIA — Messe largest and best-known industrial logistics trade show. Located in Pavilion 32, Toyota Material Handling will be focusing on lean business practices, derived from the acclaimed Toyota Production System.

Visitors will be able to gain an insight into Toyota’s approach to eliminate waste and maximise efficiency throughout manufacturing and logistic processes. Toyota is the source of lean thinking, and CeMAT 2018 will highlight how this is translated into today’s products and services.

COLLABORATION FOR THE FUTURE

Toyota’s booth at CeMAT 2018 will provide visitors with the opportunity to explore and learn about the company’s lean way of thinking. There will be a special ‘Logiconomi Forum’, where you’re welcome to come and listen to internal and external speakers who share our passion for logistics 4.0, big data, autonomous systems, safety, new energy solutions, robotics and artificial intelligence.

LOGICAL AUTOMATION

CeMAT(Asia Logistics Exhibition) will provide visitors with an insight to how Toyota uses automation in its own manufacturing and distribution processes, to streamline logistic flow. With a complete range of automated machines, Toyota can provide a simple step-by-step approach to automation, with fast commercial payback. Toyota will also be presenting an advanced new control system that seamlessly adapts operations to optimise the utilisation of available machines, avoiding traffic and increasing flow rate.

To promote global trade liberalization, Hannover Cemat Logistics Fair will be held at Shanghai Along with the booming of logistics industry in China, CeMAT ASIA has become the biggest international material handling and logistics technology trade fair.New International Expo Center, China. Asia Logistics Trade Show- International Conference on material handling, automation, transportation system and logistics.Asia Logistics Exhibition welcomes you to China!

The key is safe and reliable technique which is main exhibition focus particularly at CeMAT, ranging from complete systems and intralogistical products on processors and operating elements to software and control systems. The exhibition is divided into five sections: Pick & Pack, Move & Lift, Store & Load, Logistics IT, Manage & Service and pays special attention to the latest innovations and technologies of the industry. Internationally, it is considered as the information and communication platform with global expertise.

On the whole the organisers welcomed on the 5 days of the fair, from 19. May to 23. May 2014, about 1025 exhibitors and 53000 visitors from 65 countries on the CeMAT in Hanover.The CeMAT will take place on 5 days from Monday, 20. April to Friday, 24. April 2020 in Hanover.

Cemat ASIA — Messe largest and best-known industrial logistics trade show. Located in Pavilion 32, Toyota Material Handling will be focusing on lean business practices, derived from the acclaimed Toyota Production System.

Visitors will be able to gain an insight into Toyota’s approach to eliminate waste and maximise efficiency throughout manufacturing and logistic processes. Toyota is the source of lean thinking, and CeMAT 2018 will highlight how this is translated into today’s products and services.

COLLABORATION FOR THE FUTURE

Toyota’s booth at CeMAT 2018 will provide visitors with the opportunity to explore and learn about the company’s lean way of thinking. There will be a special ‘Logiconomi Forum’, where you’re welcome to come and listen to internal and external speakers who share our passion for logistics 4.0, big data, autonomous systems, safety, new energy solutions, robotics and artificial intelligence.

LOGICAL AUTOMATION

CeMAT(Asia Logistics Exhibition) will provide visitors with an insight to how Toyota uses automation in its own manufacturing and distribution processes, to streamline logistic flow. With a complete range of automated machines, Toyota can provide a simple step-by-step approach to automation, with fast commercial payback. Toyota will also be presenting an advanced new control system that seamlessly adapts operations to optimise the utilisation of available machines, avoiding traffic and increasing flow rate.

To promote global trade liberalization, Hannover Cemat Logistics Fair will be held at Shanghai Along with the booming of logistics industry in China, CeMAT ASIA has become the biggest international material handling and logistics technology trade fair.New International Expo Center, China. Asia Logistics Trade Show- International Conference on material handling, automation, transportation system and logistics.Asia Logistics Exhibition welcomes you to China!

Made in China 2025 focus on Shanghai 2018PTC ASIA

http://www.ptc-asia.com/index.php?lang=en

PTC ASIA, as the world's largest international professional transmission exhibition, is the most important display window of transmission and control technology. It attracts and brings together international well-known enterprises, innovative small and medium-sized enterprises and entrepreneurial enterprises, focusing on the theme of the industry and expounding the importance of power transmission and control technology for future production and application. PTC hydraulic exhibition aims to build intelligent upgrading platform for global exhibitors and buyers.

Industrial 4.0 technology brings new product development cycles, improves manufacturing efficiency and productivity, and reduces company costs. Given its capital-intensive nature, more and more advanced manufacturing economies are shifting their production resources from cheap labor-intensive countries. This is a paradigm shift that will lead to high-paying, high-value-added manufacturing jobs in the United States, provided we have the talent and skills to support it. Germany is not the only industrial country dedicated to the implementation of industrial 4. China is now implementing the "China 2025" plan based on the "industrial 4" model.

“As the core of a new round of industrial revolution, intelligent manufacturing is the main direction to realize ‘Made in China 2025’ and transform the nation from a big manufacturing country to a powerful one.” Gary Liu, Managing Director of Hannover Milano Fairs China Ltd. said, “Following the pace of the national strategy, our seven industrial shows focus on intelligent manufacturing and display smart applications, providing ideal platforms for global enterprises to improve quality, enhance efficiency, transform and upgrade.”

Human-robot collaboration is the wave of the future: Humans and robots working seamlessly alongside each other are still a ways off, but development is well underway on these so-called “cobots.” "Technology is not about competing with us humans, it's about assisting us. That is the core message conveyed by this trade fair, which has again underscored Hannover's reputation as a global hotspot for the digital transformation of industry," said Dr. Jochen Köckler, chairman of the managing board at Deutsche Messe, at the close of Hannover Messe. "The focus here has clearly been on the human element: We're the ones making the decisions and setting the course. The interaction of humans with machines and IT adds up to a huge competitive gain across manufacturing, logistics and the energy industry."

Taking place at the Shanghai New International Expo Centre (SNIEC) It ranks as the most important showcase for Hydraulic Exhibitionn and Electric drive Exhibition in Asia and, every year, is a magnet for international market leaders, innovative SMEs, start-ups, as well as for more than 80,000 visitors. After over 20 years of successful performance, The yearly growth in both Transmission Exhibition numbers and show space has proved PTC ASIA the key platform for basic parts trading of Asian markets. At a time of economic globalization, in which China’s booming demands in industry import and export have already got strong impetus, global purchasing is also taking the high road to more efficient trading. PTC ASIA is what you CANNOT afford to miss!

As China promotes the "one belt and one way" construction, it has brought a broad overseas market for the powertrain industry. Enterprises actively expand international business, strengthen the layout of the countries along the route, and achieve remarkable results. Organizers said that the exhibition also through various market channels to organize overseas buyers to purchase, when more than 80 countries and regions from the world's audience and buyers are expected to attend. Among them, the number of buyers of large domestic manufacturing enterprises will continue to grow. In 2017, the Asian International Power Transmission Exhibition was highly praised by many visiting delegations, such as Shanghai Electric, Weichai Power, Baosteel Project, Frank, Lanshi, Atlas Copco, Kaiquan Pump Industry, Shanghai Port Machinery, Jianghuai Yinlian, Hangzhou Giant Star, Zhengtai Electric, Shanghai Baosong and Shanghai BYD.

In 2016, more than 1,000 leading companies from home and abroad gathered in a display area of 70,000 sqm. 78,443 trade visitors have visited the show. In 2017, 9 Halls, continuing with the “big-industry platform”, Speed up the pace in 2018,Launch the vision of "made in China 2025"

PTC ASIA Focuses on the mega issues in industry and illustrates the enormous importance of power transmission and control technology for future production applications.

PTC ASIA, as the world's largest international professional transmission exhibition, is the most important display window of transmission and control technology. It attracts and brings together international well-known enterprises, innovative small and medium-sized enterprises and entrepreneurial enterprises, focusing on the theme of the industry and expounding the importance of power transmission and control technology for future production and application. PTC hydraulic exhibition aims to build intelligent upgrading platform for global exhibitors and buyers.

Industrial 4.0 technology brings new product development cycles, improves manufacturing efficiency and productivity, and reduces company costs. Given its capital-intensive nature, more and more advanced manufacturing economies are shifting their production resources from cheap labor-intensive countries. This is a paradigm shift that will lead to high-paying, high-value-added manufacturing jobs in the United States, provided we have the talent and skills to support it. Germany is not the only industrial country dedicated to the implementation of industrial 4. China is now implementing the "China 2025" plan based on the "industrial 4" model.

“As the core of a new round of industrial revolution, intelligent manufacturing is the main direction to realize ‘Made in China 2025’ and transform the nation from a big manufacturing country to a powerful one.” Gary Liu, Managing Director of Hannover Milano Fairs China Ltd. said, “Following the pace of the national strategy, our seven industrial shows focus on intelligent manufacturing and display smart applications, providing ideal platforms for global enterprises to improve quality, enhance efficiency, transform and upgrade.”

Human-robot collaboration is the wave of the future: Humans and robots working seamlessly alongside each other are still a ways off, but development is well underway on these so-called “cobots.” "Technology is not about competing with us humans, it's about assisting us. That is the core message conveyed by this trade fair, which has again underscored Hannover's reputation as a global hotspot for the digital transformation of industry," said Dr. Jochen Köckler, chairman of the managing board at Deutsche Messe, at the close of Hannover Messe. "The focus here has clearly been on the human element: We're the ones making the decisions and setting the course. The interaction of humans with machines and IT adds up to a huge competitive gain across manufacturing, logistics and the energy industry."

Taking place at the Shanghai New International Expo Centre (SNIEC) It ranks as the most important showcase for Hydraulic Exhibitionn and Electric drive Exhibition in Asia and, every year, is a magnet for international market leaders, innovative SMEs, start-ups, as well as for more than 80,000 visitors. After over 20 years of successful performance, The yearly growth in both Transmission Exhibition numbers and show space has proved PTC ASIA the key platform for basic parts trading of Asian markets. At a time of economic globalization, in which China’s booming demands in industry import and export have already got strong impetus, global purchasing is also taking the high road to more efficient trading. PTC ASIA is what you CANNOT afford to miss!

As China promotes the "one belt and one way" construction, it has brought a broad overseas market for the powertrain industry. Enterprises actively expand international business, strengthen the layout of the countries along the route, and achieve remarkable results. Organizers said that the exhibition also through various market channels to organize overseas buyers to purchase, when more than 80 countries and regions from the world's audience and buyers are expected to attend. Among them, the number of buyers of large domestic manufacturing enterprises will continue to grow. In 2017, the Asian International Power Transmission Exhibition was highly praised by many visiting delegations, such as Shanghai Electric, Weichai Power, Baosteel Project, Frank, Lanshi, Atlas Copco, Kaiquan Pump Industry, Shanghai Port Machinery, Jianghuai Yinlian, Hangzhou Giant Star, Zhengtai Electric, Shanghai Baosong and Shanghai BYD.

In 2016, more than 1,000 leading companies from home and abroad gathered in a display area of 70,000 sqm. 78,443 trade visitors have visited the show. In 2017, 9 Halls, continuing with the “big-industry platform”, Speed up the pace in 2018,Launch the vision of "made in China 2025"

PTC ASIA Focuses on the mega issues in industry and illustrates the enormous importance of power transmission and control technology for future production applications.

Read More: http://www.ptc-asia.com/index.php?lang=en

2018年9月12日星期三

CHIC Shanghai _ Fashion Trade Show

CHIC Shanghai _ Fashion Trade Show

As the largest and most influential fashion show in Asia, CHIC (Fashion Trade Show) has an exhibition area of 100,000 square meters, more than 125,000 trade visitors and 20 countries and regions , More than 1,000 brands of these brilliant figures.

CHIC(Fashion Trade Show) is always a function of a set of trade negotiations, channel development, resource integration, international cooperation, market inspection, fashion editing, cross-border cooperation, Anchoring capital and other integrated quality integrated resource platforms; 25 years, CHIC Fashion Trade Show has been based on changes in the industry and the market continues to innovate and grow with the clothing brand in China, is the Chinese clothing brand recognized by the industry and the facilitator of Market development and witness.

The clothing industry of China today and consumption of a long, fast, variable, more emphasizes the role of the platform indispensable to the development of the company. More and more individual brand companies, manufacturing companies, apparel-related industries and terminal channels to participate in the CHIC fashion show, and each has revenue. CHIC (Fashion Trade Show) is also a new form of extension of the exhibition features, a comprehensive upgrade service system, to enhance the value of the exhibition platform.

IEDA

Since its inception, CHIC(Fashion Trade Show) organizers put the "guide the progress of China's garment industry, promote the development of China's clothing brand" as a show purpose. CHIC's core philosophy is: to create clothing brand promotion, market development, wealth creation of international first-class business platform;

shaping the most fashion sense, the most cutting-edge and trend-driven, the most creative and cross-inspired fashion platform; The global clothing brand to share and configure their related resources required for the influential exchange platform.

CHIC(Fashion Trade Show) has always been the forerunner of fashion and healthy lifestyle; CHIC(Fashion Trade Show) has always been a comprehensive integrator of the brand's sustainable development and market development resources; Fashion Trade Show is always an excellent provider of high-end, professional, humane services and effective solutions . CHIC has become China's garment industry and the world's "benchmark", "barometer."

Evolution

Since 1993, CHIC(Fashion Trade Show) has held 5 consecutive sessions in the China International Trade Center. The arrival of international masters and international brands has opened up the Chinese garment industry, which is still in its infancy of brand development. It has also strengthened the vision of many Chinese garments People self-development, self-revitalization of the beliefs and determination, a number of far-sighted enterprises began to take the pace of brand building.

In 1998, CHIC(Fashion Trade Show) moved to China International Exhibition Center (the old hall). During the past ten years, CHIC organizers organized professional promotion and business activities, which made CHIC's organization and service system more professional and in-depth. During this period, CHIC's professionalism, position in the industry and international influence are established, CHIC to specialization, internationalization direction to achieve a leap-forward development.

2008, CHIC(Fashion Trade Show) fought in Beijing China International Exhibition Center (New Hall), the organizers overview of the overall situation of the future direction of the brand, competitive situation, the operating mode to make accurate judgments, hold high the banner of "innovation" As the breakthrough point, the "breakthrough and innovation, transformation and upgrading." In the next decade, the global economic focus of the transfer and reallocation of global resources is the trend, more powerful Chinese brand, will have more right to speak to establish a new rule. The CHIC as Asia's largest and influential professional clothing exhibition, in promoting the development and expansion of China's clothing brand in the process also completed its own brand-building gorgeous turn. CHIC brand and the depth of cooperation, to seek the perfect combination of market and brand, has become China's clothing brand sustained and stable development of one of the magic.

In 2010, CHIC(Fashion Trade Show) has been brilliant through 18 years, has a series of extraordinary figures: 100,000 square meters of exhibition area, more than 100,000 professional visitors, more than 20 countries and regions exhibitors and more than a thousand exhibition Brand ...... CHIC has been recognized as the industry's clothing brand promotion, market development, innovation show, the trend of publishing, wealth creation, resource sharing and international exchange of the best platform. At the same time, with the exhibition of the rising fashion, a variety of cultural, artistic, creative and other cross-border integration of resources so that each year in March CHIC fashion industry as well as social focus.

In 2011, CHIC launched a new "discovery" tour, attracted from 19 countries and regions, more than 1,000 Chinese and foreign apparel brands participating in the same period successfully held more than 60 games, more than 110,000 domestic and foreign visitors to the scene, Exhibitors and visitors with the perfect platform for CHIC business docking. "China International Clothing & Accessories Fair thriving than expected, is impressive." March 29, the CPC Central Committee Political Bureau, Vice Premier Zhang Dejiang visited the 19th China International Clothing & Accessories Fair evaluation. "Although the new exhibition hall is far away from the urban area, but to showcase the business and the audience is still a lot, which fully shows that the exhibition as an industry link and window in the industry very attractive, businesses and enterprises through the exhibition exchange of information, Communication business, but also the performance of the industry a strong vitality.

2012, CHIC(Fashion Trade Show) ushered in the 20th birthday, its increasingly extensive international influence to promote more clothing brands to participate in CHIC2012 to, from the United States, France, Italy, Germany, Spain, Korea, Japan, Hong Kong, Greece, Turkey, Israel and other 21 countries and regions, nearly 1,000 clothing brands exhibitors. The exhibition site will usher in more than 110,000 professional visitors to the scene. Despite the active participation of domestic and foreign customers, CHIC organizers did not simply expand the exhibition area and brand number, but will focus on improving the quality of exhibitors, select more more strength and development potential of the clothing brand, so that businesses have more exposure to good Brand and business negotiation opportunities. There will also be a series of highlights such as: CHIC 20 anniversary PARTY, the China Garment Forum, Jack the eighth annual awards ceremony of China's clothing brand, the Chinese clothing distribution, etc., these activities greatly enriched the CHIC2012 exhibition content , The CHIC2012 into a fusion of fashion, business and academic in a clothing industry event.

In 2013, CHIC(Fashion Trade Show) to "Lian Lian" as the theme, called on enterprises to do steady market with great concentration, good products, new models, innovation, and further enhance endogenous power, "Li Lian" brand core values to adapt to the new Period of changes in market demand and create the Chinese garment industry in the international economic competition in the brand development of new advantages, based on the commanding heights of the industrial value chain. It can be said, CHIC2013 is a re-examine and enhance the process of self, through the depth of the growth of their own endogenous driving force to build new development advantages, once again take a solid step forward.

Exhibition contact (Overseas)

Lv jiang

Telephone: 86-10-65050617

Fax: 86-10-65053260

Zip code: 100004

Email:lvjiang@cwtc.com

Address: Room 515, China World Office Building 2, No.1 Jianguomenwai Ave., Chaoyang District, Beijing, China

Website:http://en.chiconline.com.cn/

As the largest and most influential fashion show in Asia, CHIC (Fashion Trade Show) has an exhibition area of 100,000 square meters, more than 125,000 trade visitors and 20 countries and regions , More than 1,000 brands of these brilliant figures.

CHIC(Fashion Trade Show) is always a function of a set of trade negotiations, channel development, resource integration, international cooperation, market inspection, fashion editing, cross-border cooperation, Anchoring capital and other integrated quality integrated resource platforms; 25 years, CHIC Fashion Trade Show has been based on changes in the industry and the market continues to innovate and grow with the clothing brand in China, is the Chinese clothing brand recognized by the industry and the facilitator of Market development and witness.

The clothing industry of China today and consumption of a long, fast, variable, more emphasizes the role of the platform indispensable to the development of the company. More and more individual brand companies, manufacturing companies, apparel-related industries and terminal channels to participate in the CHIC fashion show, and each has revenue. CHIC (Fashion Trade Show) is also a new form of extension of the exhibition features, a comprehensive upgrade service system, to enhance the value of the exhibition platform.

IEDA

Since its inception, CHIC(Fashion Trade Show) organizers put the "guide the progress of China's garment industry, promote the development of China's clothing brand" as a show purpose. CHIC's core philosophy is: to create clothing brand promotion, market development, wealth creation of international first-class business platform;

shaping the most fashion sense, the most cutting-edge and trend-driven, the most creative and cross-inspired fashion platform; The global clothing brand to share and configure their related resources required for the influential exchange platform.

CHIC(Fashion Trade Show) has always been the forerunner of fashion and healthy lifestyle; CHIC(Fashion Trade Show) has always been a comprehensive integrator of the brand's sustainable development and market development resources; Fashion Trade Show is always an excellent provider of high-end, professional, humane services and effective solutions . CHIC has become China's garment industry and the world's "benchmark", "barometer."

Evolution

Since 1993, CHIC(Fashion Trade Show) has held 5 consecutive sessions in the China International Trade Center. The arrival of international masters and international brands has opened up the Chinese garment industry, which is still in its infancy of brand development. It has also strengthened the vision of many Chinese garments People self-development, self-revitalization of the beliefs and determination, a number of far-sighted enterprises began to take the pace of brand building.

In 1998, CHIC(Fashion Trade Show) moved to China International Exhibition Center (the old hall). During the past ten years, CHIC organizers organized professional promotion and business activities, which made CHIC's organization and service system more professional and in-depth. During this period, CHIC's professionalism, position in the industry and international influence are established, CHIC to specialization, internationalization direction to achieve a leap-forward development.

2008, CHIC(Fashion Trade Show) fought in Beijing China International Exhibition Center (New Hall), the organizers overview of the overall situation of the future direction of the brand, competitive situation, the operating mode to make accurate judgments, hold high the banner of "innovation" As the breakthrough point, the "breakthrough and innovation, transformation and upgrading." In the next decade, the global economic focus of the transfer and reallocation of global resources is the trend, more powerful Chinese brand, will have more right to speak to establish a new rule. The CHIC as Asia's largest and influential professional clothing exhibition, in promoting the development and expansion of China's clothing brand in the process also completed its own brand-building gorgeous turn. CHIC brand and the depth of cooperation, to seek the perfect combination of market and brand, has become China's clothing brand sustained and stable development of one of the magic.

In 2010, CHIC(Fashion Trade Show) has been brilliant through 18 years, has a series of extraordinary figures: 100,000 square meters of exhibition area, more than 100,000 professional visitors, more than 20 countries and regions exhibitors and more than a thousand exhibition Brand ...... CHIC has been recognized as the industry's clothing brand promotion, market development, innovation show, the trend of publishing, wealth creation, resource sharing and international exchange of the best platform. At the same time, with the exhibition of the rising fashion, a variety of cultural, artistic, creative and other cross-border integration of resources so that each year in March CHIC fashion industry as well as social focus.

In 2011, CHIC launched a new "discovery" tour, attracted from 19 countries and regions, more than 1,000 Chinese and foreign apparel brands participating in the same period successfully held more than 60 games, more than 110,000 domestic and foreign visitors to the scene, Exhibitors and visitors with the perfect platform for CHIC business docking. "China International Clothing & Accessories Fair thriving than expected, is impressive." March 29, the CPC Central Committee Political Bureau, Vice Premier Zhang Dejiang visited the 19th China International Clothing & Accessories Fair evaluation. "Although the new exhibition hall is far away from the urban area, but to showcase the business and the audience is still a lot, which fully shows that the exhibition as an industry link and window in the industry very attractive, businesses and enterprises through the exhibition exchange of information, Communication business, but also the performance of the industry a strong vitality.

2012, CHIC(Fashion Trade Show) ushered in the 20th birthday, its increasingly extensive international influence to promote more clothing brands to participate in CHIC2012 to, from the United States, France, Italy, Germany, Spain, Korea, Japan, Hong Kong, Greece, Turkey, Israel and other 21 countries and regions, nearly 1,000 clothing brands exhibitors. The exhibition site will usher in more than 110,000 professional visitors to the scene. Despite the active participation of domestic and foreign customers, CHIC organizers did not simply expand the exhibition area and brand number, but will focus on improving the quality of exhibitors, select more more strength and development potential of the clothing brand, so that businesses have more exposure to good Brand and business negotiation opportunities. There will also be a series of highlights such as: CHIC 20 anniversary PARTY, the China Garment Forum, Jack the eighth annual awards ceremony of China's clothing brand, the Chinese clothing distribution, etc., these activities greatly enriched the CHIC2012 exhibition content , The CHIC2012 into a fusion of fashion, business and academic in a clothing industry event.

In 2013, CHIC(Fashion Trade Show) to "Lian Lian" as the theme, called on enterprises to do steady market with great concentration, good products, new models, innovation, and further enhance endogenous power, "Li Lian" brand core values to adapt to the new Period of changes in market demand and create the Chinese garment industry in the international economic competition in the brand development of new advantages, based on the commanding heights of the industrial value chain. It can be said, CHIC2013 is a re-examine and enhance the process of self, through the depth of the growth of their own endogenous driving force to build new development advantages, once again take a solid step forward.

Exhibition contact (Overseas)

Lv jiang

Telephone: 86-10-65050617

Fax: 86-10-65053260

Zip code: 100004

Email:lvjiang@cwtc.com

Address: Room 515, China World Office Building 2, No.1 Jianguomenwai Ave., Chaoyang District, Beijing, China

Website:http://en.chiconline.com.cn/

【AFF•アパレル展示会】東京2018

【AFF·アパレル展示会】東京2018

名称:中国高級アパレル&素材展示商談会ーAFFセレクション会場:サンシャインシティ文化会館

会期:2018年9月26日(水)—28日(金)

会場:〒170-8630東京都豊島区東池袋3−1−4

展示内容: アパレル、素材、服飾品、副資材、ホームテキスタイルなど

主催:AFF株式会社、一般社団法人日中経済貿易センター

運営: AFF事務局

AFF(アパレル展示会)は、日本での最大級の繊維•アパレルOEM/ODM展示会です。2003年から毎年、春は大阪、秋は東京で開催し、今回は33回を迎えます。

出展企業は、生産供給者であり、生産調達者でもあります。素材・副資材の調達や、デザイン・提案も可能です。日本に代理店を有する企業もあり、日本、カンボジア、ミャンマー、バングラデシュ、インド、スリランカ、ラオスなどに自社工場を有する企業もあります。

この展覧会は、中国や日本の産業からの熱狂的な反応と賞賛を受け、日本の地方自治体や経済貿易団体の支援も受けていました。バックアップユニットを構築するために展示会に参加している:大阪府大阪、経済産業省の近畿局、日本商工会議所、大阪商工会議所、日本貿易振興機構(ジェトロ)、日本貿易振興機構(ジェトロ)大阪本部、日本ファイバ出力の組み合わせ、日本の繊維の入力の組み合わせ、共同ファッション関西、日本ファッション協会、日本アパレル産業協会•ファッション、インテリアテキスタイル日本の協会、一般的にはショッピングセンターの日本協議会、日本国際貿易促進協会、東海日中貿易センター、大阪国際空港では、市議会、大名(Daima Co.)、信用取引所(Credit Exchange)が見られます。

ショービジネスの効果を追求するには、show主催者の努力以来、日本のOEM•ODMの展示会(アパレル展示会)の代表になるために中国と日本の産業界に欠かせないと効率的なプラットフォームを構築し、基本的に大阪に東京で毎年春と秋を維持展覧会の頻度。近年、アジア地域では日本の産業需要が多様化し、東南アジアや南アジア諸国の調達需要が増加しており、いわゆる「中国+1」の傾向がますます明らかになっています。同展示会で「中国+1」オプションの要求を実装して買い手を満たすために、展示会は、より多くのアジアの出展者と、さらにその業界での影響力を拡大するために、既存の取引プラットフォームをフルに活用するために、当事者をもたらすための努力を追加したいと考えています。この展覧会は、2014年9月22日の展示会でAFFに改名されました。

[AFF·アパレル展示会出展規模と効果]

展示会に出展された繊維・服飾品の輸出能力は、最新の衣類関連OEM・ODM製品とダイナミクスを網羅し、日本における対応する製品輸入の15%以上を占めた。統計によると、展示期間中の出展者の期待回転率と意図的な売上高は90%と高く、平均して50人以上の有効な顧客を有し、そのうちの60%が新規顧客です。

[AFF(アパレル展示会)·アパレル展示会展示の範囲]

服飾:すべての種類のファッションとメンズ、女性と子供の服。

ファブリック素材、ファブリック、アクセサリー、寝具、織物、家庭用寝具、スリーピース製品、ファッションアクセサリー、アクセサリー、バッグ、靴、傘。

アパレル展示会お問い合わせ:

担当:黄雨晨

連絡先:el.86-10-65285310 Fax.86-10-65123051

住所:大阪市中央区久太郎町4丁目1番3号大阪センタービル2階

E-mail:huangyuchen@asiafashionfair.jp

http://www.asiafashionfair.jp/exhibitor/

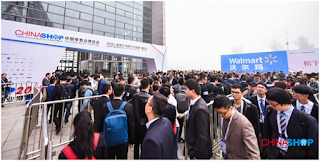

CHINASHOP 2018 _ CHINA RETAIL TRADE FAIR

KUNMING, China, June 28, 2018

In recent years, the development of China retail industry has attracted world-wide attention with online and offline convergence, mobile payment, unattended retail, cross-border retail, and other concepts and models that define New Retail and mark the evolution of the country's retail sector. At the same time, China's New Retail model has been increasingly adopted by a growing number of countries. As some of the world's most dynamic emerging economies, Southeast Asian countries are well positioned to take advantage of the New Retail model, and China is the market they are looking to for inspiration and as the model to emulate.

As the largest and most professional retail trade fair not only in China, but also the whole of Asia, CHINASHOP(China Retail Trade Fair) brings together China's top New Retail companies. The exhibition will cover the whole gamut of products related to New Retail concepts, including mobile payment, radio-frequency identification (RFID), warehousing logistics, augmented reality (AR), and virtual reality (VR), as well as management systems. Nearly 1,000 companies specializing in the provision of equipment and technical solutions for New Retail, including Alibaba, Sunmi and Hisense etc., will debut and showcase their latest products in the 100,000 square meter exhibition area. At the concurrently held China National Retail Congress, the largest and most authoritative retail conference in China, 3,000 opinion leaders and company executives from across the retail sector will come together to discuss the latest development trends.

CHINASHOP (China Retail Trade Fair) will take place November 1-3 in Kunming, Yunnan province. Join China's top New Retail firms in witnessing the development of the industry together.

Contact Us

Mr. Jason Guo

Tel: +86-10-68019941

E-mail: guoh@chinashop.cc

Website: http://en.chinashop.cc/AboutChinaShop.htm

In recent years, the development of China retail industry has attracted world-wide attention with online and offline convergence, mobile payment, unattended retail, cross-border retail, and other concepts and models that define New Retail and mark the evolution of the country's retail sector. At the same time, China's New Retail model has been increasingly adopted by a growing number of countries. As some of the world's most dynamic emerging economies, Southeast Asian countries are well positioned to take advantage of the New Retail model, and China is the market they are looking to for inspiration and as the model to emulate.

As the largest and most professional retail trade fair not only in China, but also the whole of Asia, CHINASHOP(China Retail Trade Fair) brings together China's top New Retail companies. The exhibition will cover the whole gamut of products related to New Retail concepts, including mobile payment, radio-frequency identification (RFID), warehousing logistics, augmented reality (AR), and virtual reality (VR), as well as management systems. Nearly 1,000 companies specializing in the provision of equipment and technical solutions for New Retail, including Alibaba, Sunmi and Hisense etc., will debut and showcase their latest products in the 100,000 square meter exhibition area. At the concurrently held China National Retail Congress, the largest and most authoritative retail conference in China, 3,000 opinion leaders and company executives from across the retail sector will come together to discuss the latest development trends.

CHINASHOP (China Retail Trade Fair) will take place November 1-3 in Kunming, Yunnan province. Join China's top New Retail firms in witnessing the development of the industry together.

Contact Us

Mr. Jason Guo

Tel: +86-10-68019941

E-mail: guoh@chinashop.cc

Website: http://en.chinashop.cc/AboutChinaShop.htm

2018年7月7日星期六

【AFF·アパレル展示会】東京2018

【AFF·アパレル展示会】東京2018

会場:サンシャインシティ文化会館

会期:2018年9月26日(水)—28日(金)

会場:〒170-8630東京都豊島区東池袋3−1−4

展示内容: アパレル、素材、服飾品、副資材、ホームテキスタイルなど

主催:AFF株式会社、一般社団法人日中経済貿易センター

運営: AFF事務局

出展企業は、生産供給者であり、生産調達者でもあります。素材・副資材の調達や、デザイン・提案も可能です。日本に代理店を有する企業もあり、日本、カンボジア、ミャンマー、バングラデシュ、インド、スリランカ、ラオスなどに自社工場を有する企業もあります。

この展覧会は、中国や日本の産業からの熱狂的な反応と賞賛を受け、日本の地方自治体や経済貿易団体の支援も受けていました。バックアップユニットを構築するために展示会に参加している:大阪府大阪、経済産業省の近畿局、日本商工会議所、大阪商工会議所、日本貿易振興機構(ジェトロ)、日本貿易振興機構(ジェトロ)大阪本部、日本ファイバ出力の組み合わせ、日本の繊維の入力の組み合わせ、共同ファッション関西、日本ファッション協会、日本アパレル産業協会•ファッション、インテリアテキスタイル日本の協会、一般的にはショッピングセンターの日本協議会、日本国際貿易促進協会、東海日中貿易センター、大阪国際空港では、市議会、大名(Daima Co.)、信用取引所(Credit Exchange)が見られます。

ショービジネスの効果を追求するには、show主催者の努力以来、日本のOEM•ODMの展示会の代表になるために中国と日本の産業界に欠かせないと効率的なプラットフォームを構築し、基本的に大阪に東京で毎年春と秋を維持展覧会の頻度。近年、アジア地域では日本の産業需要が多様化し、東南アジアや南アジア諸国の調達需要が増加しており、いわゆる「中国+1」の傾向がますます明らかになっています。同展示会で「中国+1」オプションの要求を実装して買い手を満たすために、展示会は、より多くのアジアの出展者と、さらにその業界での影響力を拡大するために、既存の取引プラットフォームをフルに活用するために、当事者をもたらすための努力を追加したいと考えています。この展覧会は、2014年9月22日の展示会でAFFに改名されました。

[AFF·アパレル展示会出展規模と効果]

展示会に出展された繊維・服飾品の輸出能力は、最新の衣類関連OEM・ODM製品とダイナミクスを網羅し、日本における対応する製品輸入の15%以上を占めた。統計によると、展示期間中の出展者の期待回転率と意図的な売上高は90%と高く、平均して50人以上の有効な顧客を有し、そのうちの60%が新規顧客です。

[AFF·アパレル展示会展示の範囲]

服飾:すべての種類のファッションとメンズ、女性と子供の服。

ファブリック素材、ファブリック、アクセサリー、寝具、織物、家庭用寝具、スリーピース製品、ファッションアクセサリー、アクセサリー、バッグ、靴、傘。

アパレル展示会お問い合わせ:

担当:黄雨晨

連絡先:el.86-10-65285310 Fax.86-10-65123051

住所:大阪市中央区久太郎町4丁目1番3号大阪センタービル2階

E-mail:huangyuchen@asiafashionfair.jp

Website:http://www.asiafashionfair.jp/exhibitor/

订阅:

博文 (Atom)